Frame Design for Quadcopter

Overview:

Frame design is another compelling part of this project. As a lightweight and compact frame is essential to make a drone fly, so it was our priority to make frame as much as lighter as we can, by keeping safety concerns in mind. After spending some couple of days we finalized a design and one of our friends started to work on it. But due covid-19 pandemic and chances of early closer of university, our instructor apprise us to focus on flight controller design and components interface. So, we provided our design and dimensions, according to our requirement, to sir Azmat for Soldiworks design. We remained in contact with sir during the design process and thanks to him for giving us explanation about every step. Now here we present the frame design procedure, failure in 3D printing, and final product.

Click Here to download SolidWorks design.

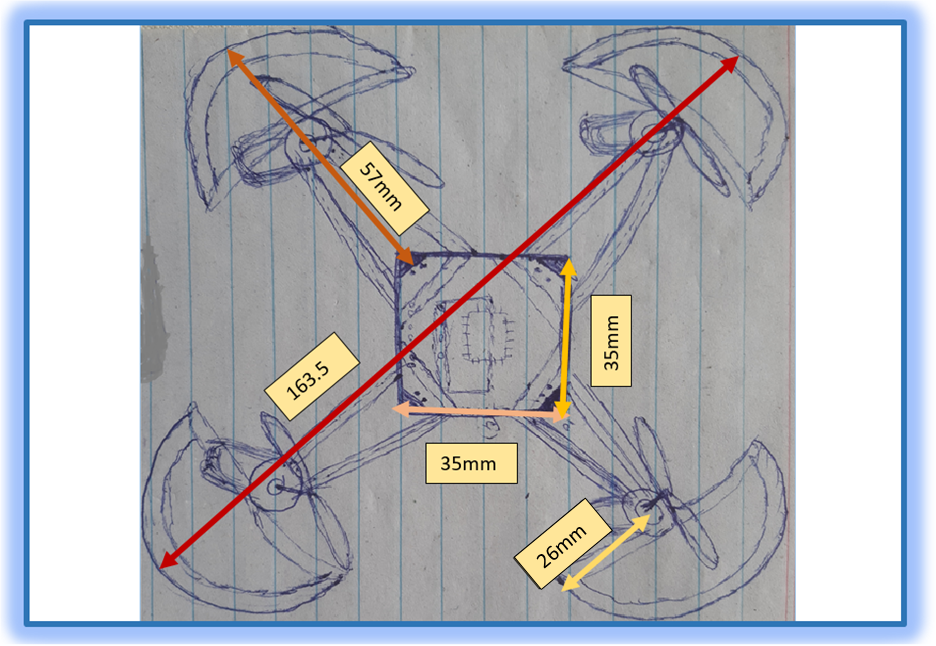

Dimensions Of The Quadcopter:

Below mentioned figure represents the dimension of our designed quadcopter. Here we have tried our best to reduce maximum material from the case so that it can be lighter. Also we have designed propeller guards for safety concerns of propellers.

Solid Work Design:

So here is the quadcopter frame after done with the design procedure in Solidworks.

First 3D Frame:

In the firs attempt we tried to use nylon to print the frame as it is a lightweight material. Everything was going well for the first two hours but then frame started to get distorted and the result were not that inspiring. Here is the output:

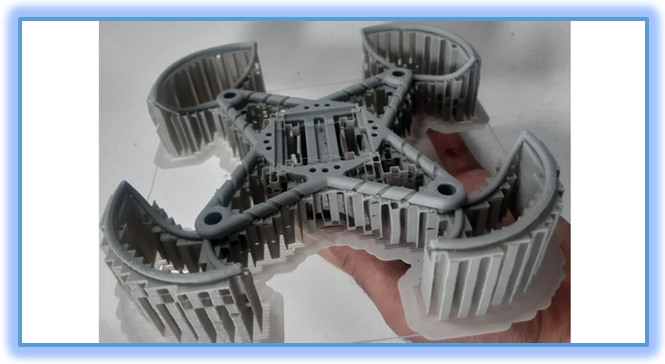

Second Attempt For 3D Frame:

After not getting any success with nylon, next option was to change the material. We then printed the frame with PLA. PLA is ideal for 3D prints where aesthetics are important. Due to its lower printing temperature is easier to print with and therefore better suited for parts with fine details. But in our case due to complexity of design, it did not work. Here is the result:

3D printing process takes a lot of time. In our case it took almost 8 hours just to complete a single design. Here is a video shows the complete process of 3D printing of our frame.

Successful Printed Frame:

After two attempts, one with nylon and another with PLA material, next we decided to print the frame using ABS. ABS has superior mechanical properties but is harder to print as compared to PLA. It also makes the design too heavy, but we had no other option, so we printed our frame using PLA material. Finally this material worked. Here is the final result:

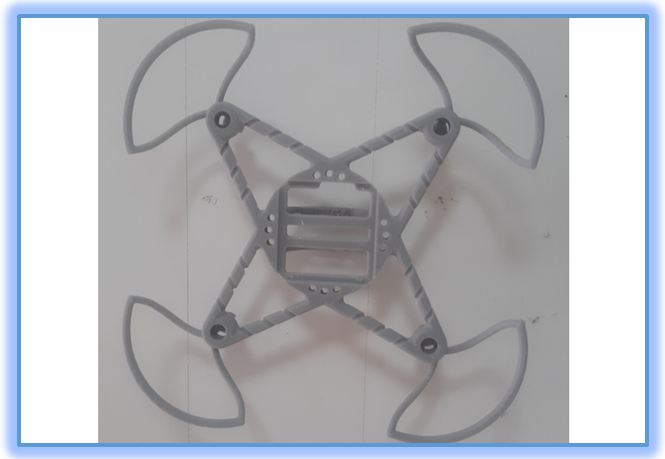

Final Product:

Here is the final frame of our quadcopter design.